Introduction

In the world of cement production, grinding is a crucial process that ultimately determines the quality of the final product. Traditionally, this process has been carried out using ball mills, which consume a significant amount of energy and are known for their limited efficiency. However, with the advent of vertical roller mills, a game-changing technology has emerged, revolutionizing the cement grinding industry. In this article, we will explore the unmatched advantages of vertical roller mills and how they can transform cement production.

Revolutionize Cement Grinding: Unleash the Power of Vertical Roller Mills

Vertical roller mills are a modern and efficient way to grind cement. Unlike traditional ball mills, vertical roller mills use a combination of compression and shear forces to crush the material into fine particles. This results in a more efficient grinding process, as the vertical roller mill requires less energy and generates less heat compared to ball mills. Additionally, vertical roller mills are capable of drying the material during the grinding process, eliminating the need for a separate drying unit.

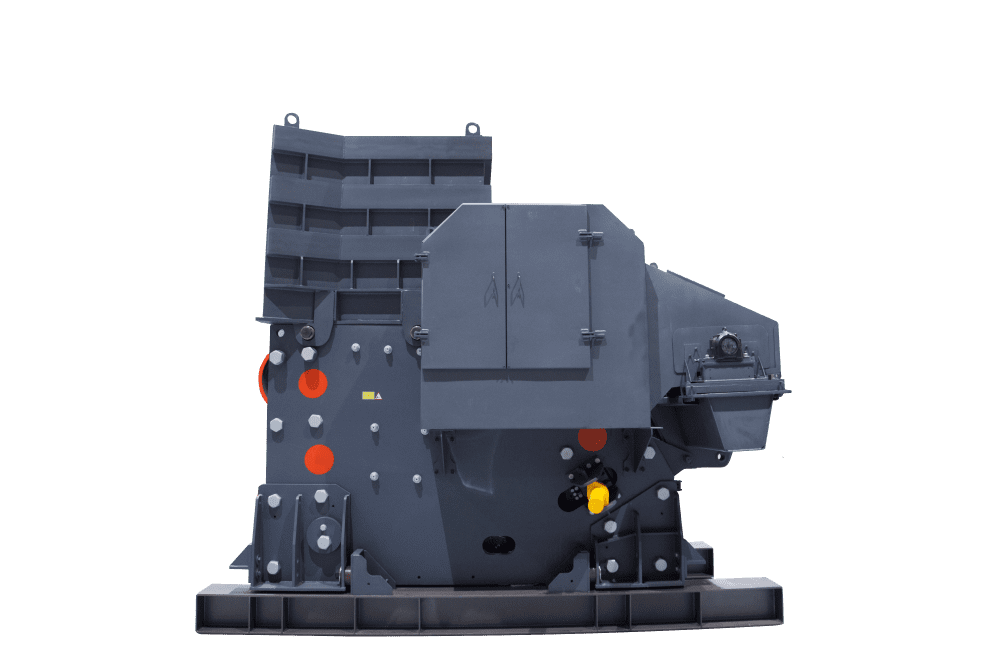

At Zenith, a leading machinery manufacturing company from China, we have embraced the power of vertical roller mills and developed cutting-edge solutions for cement grinding. Our range of vertical roller mills includes advanced features like high-efficiency separators, hydraulic systems, and precise control of grinding pressure and temperature. With our state-of-the-art technology, we ensure that our vertical roller mills deliver unparalleled performance and enhance cement grinding efficiency.

Discover the Game-Changing Technology that Enhances Cement Grinding Efficiency

The advantages of vertical roller mills in cement grinding are numerous. First and foremost, these mills have a significantly lower energy consumption compared to traditional ball mills. This not only reduces operational costs but also contributes to a more sustainable and environmentally friendly cement production process. Additionally, the vertical roller mill has a smaller footprint, allowing for easier integration into existing cement plants.

One of the key features of vertical roller mills is their ability to grind materials with high moisture content. Unlike ball mills, which are prone to clogging and require extensive maintenance, vertical roller mills can handle materials with moisture levels up to 20%. This makes them ideal for grinding materials like slag and coal, which often contain moisture. Furthermore, the vertical roller mill can also operate with a higher grinding pressure, resulting in finer and more uniform particle size distribution.

Transforming Cement Production: Embrace the Unmatched Advantages of Vertical Roller Mills

By embracing the unmatched advantages of vertical roller mills, cement producers can revolutionize their grinding process and unlock significant benefits. The enhanced efficiency and lower energy consumption of vertical roller mills translate into higher productivity and cost savings for cement plants. Furthermore, the smaller footprint and ability to grind materials with high moisture content make vertical roller mills a versatile and sustainable solution for cement grinding.

At Zenith, we are committed to delivering game-changing technology for cement production. Our range of vertical roller mills is designed to optimize grinding efficiency, reduce operational costs, and ensure the highest quality of the final product. With our expertise and cutting-edge solutions, we empower cement producers to embrace the power of vertical roller mills and transform their grinding process for a more sustainable and profitable future. Get in touch with our sales office in South Africa to discover how our vertical roller mills can revolutionize cement grinding.